Main Specification

VERTICAL FINE BORING & MILLING MACHINE T7220D

This serial model can be widely used in boring automobile engine cylinders

E-mail: sales@apsmachinery.com

Consult NowThis serial model can be widely used in boring automobile engine cylinders, cylinder sleeves of diesel engines and compressors,as well as various high precision holes boring,surface milling grinding of other workpieces.

Stepless of spindle turning ,feeding and table travelling.

Rotating speed and feed of spindle as well as the movement of worktable is free-setup,automatical retuming of spindle can be realized

Longitudingal and cross movement of table

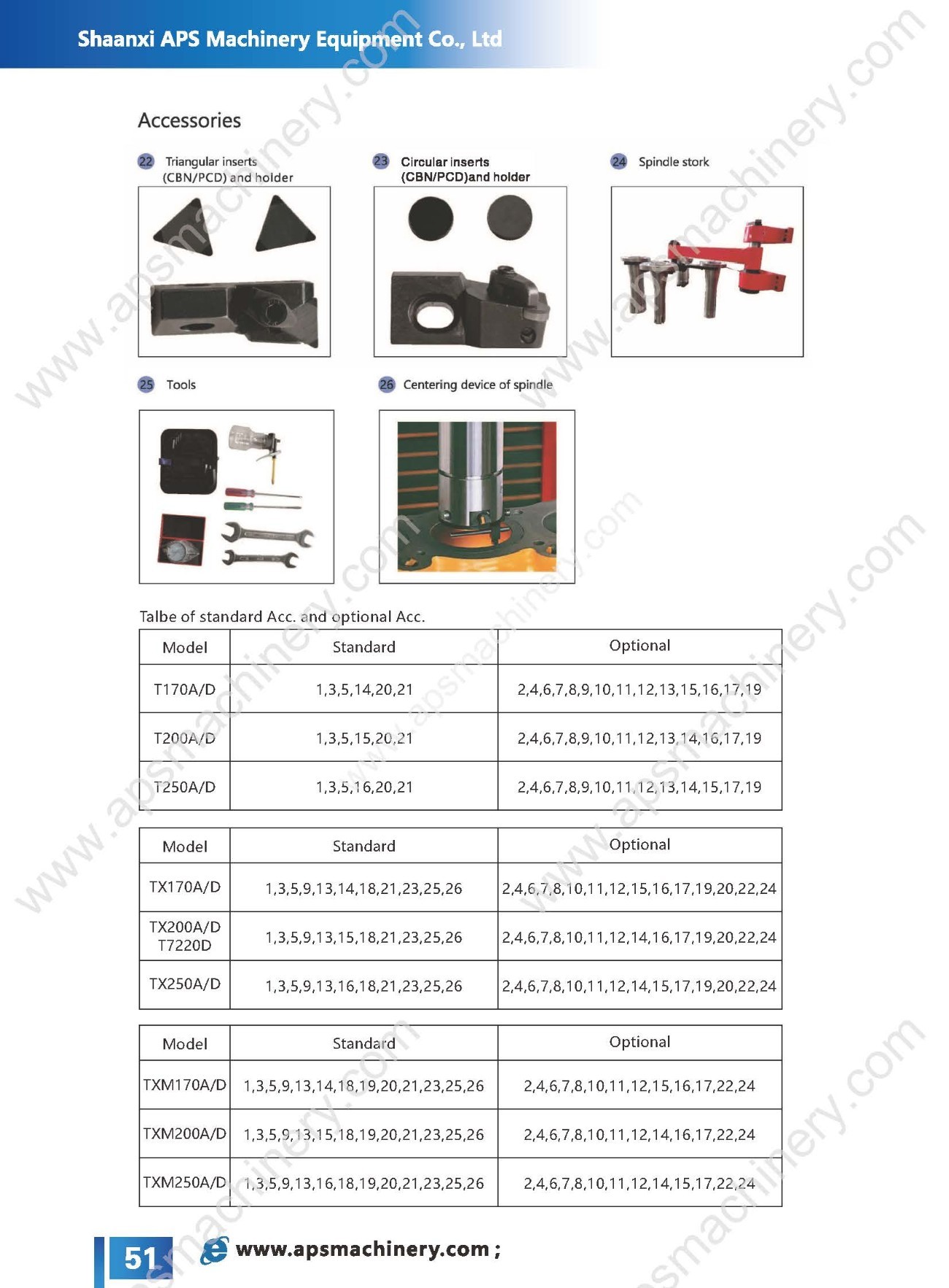

Complete set of accessories of boring, milling drilling&reaming and easy exchange

Tool fast centering device

Tool measuring device

Boring depth control device

Table with digital readout for jig borer machine

ITEMS | Mm | T7220D | |

Max. Boring diameter | Mm | φ200 | |

Max. Boring depth | Mm | 500 | |

Max.milling area | Mm | 400x1000 | |

Max. drilling& reaming diameter | r/min | φ30 | |

Spindle speed | Mm/min | 120-860 | |

Feeding of the spindle | Mm/mim | 14-900 | |

Rapid moving speed of he spindle | Mm | 900 | |

Spindle travel | Mm | 700 | |

Distance between spindle end face and table | Mm | 0-700 | |

Distance between spindle axis and carriage vertical plane | Mm/mim | 365 | |

Longitudinal feed of worktable | Mm/mim | 32-1350 | |

Rapid moving speed of the table longitudinal travel | Mm | 1350 | |

Max. longitudinal travel of the working table | Mm | 1500 | |

Max. cross travel of the working table | Mm | 200 | |

Worktable size(W*L) | Mm | 500*1500 | |

Dimensional precision of boring hole |

|

| H7 |

Machining precision | Roundness | Mm | 0.005 |

Cylindricity | Mm | 0.01/300 | |

Milling flatness | Mm | 0.1 | |

Surface roughness | Boring | Um | Ra2.5 |

Milling | Um | Ra3.2 | |

Main molar power | KW | 5.5 | |

overall dimensions (L*W*H) | Cm | 260 163 230 | |

Packing dimensions(L*W*H) | Cm | 225 190*228 | |

N.W/G.W. | kg | 3500/3800 | |

-

File size: 1.7MB

Classification:

Boring

Key words:

Previous Page

RELATED PRODUCTS

Contact Us

Thank you again for choosing us.

We will arrange for after-sales experts to contact you as soon as possible to help you find products or solutions that meet your needs and goals.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

E-mail: sales@apsmachinery.com

No.311,Panlong district ,Kunming,Yunan,China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.